Unlock Your Dream Home with Borey Peng Huot’s Phum Morakot Project!

Exciting news for aspiring homeowners! The highly anticipated Phum Morakot project by Borey Peng Huot is set to officially open its doors for sales from May 16 to 18, 2025. After witnessing overwhelming interest during the Pre-Sale phase, we’re thrilled to announce this exclusive opportunity for you to secure your place in this beautiful […]

Experience the Future of Comfort with GGear and LG Electronics’ New Air Conditioner

In an exciting development for the Cambodian market, GGear Group has partnered with LG Electronics to unveil the revolutionary LG AI Air air conditioner, a perfect blend of modern technology, energy efficiency, and user-friendly design. This cutting-edge product was officially launched on May 8, 2025, at the prestigious Saint-Gréla Hotel in Phnom Penh, drawing […]

The Future is Here: A New Beginning | Countdown to 2025 CICEE

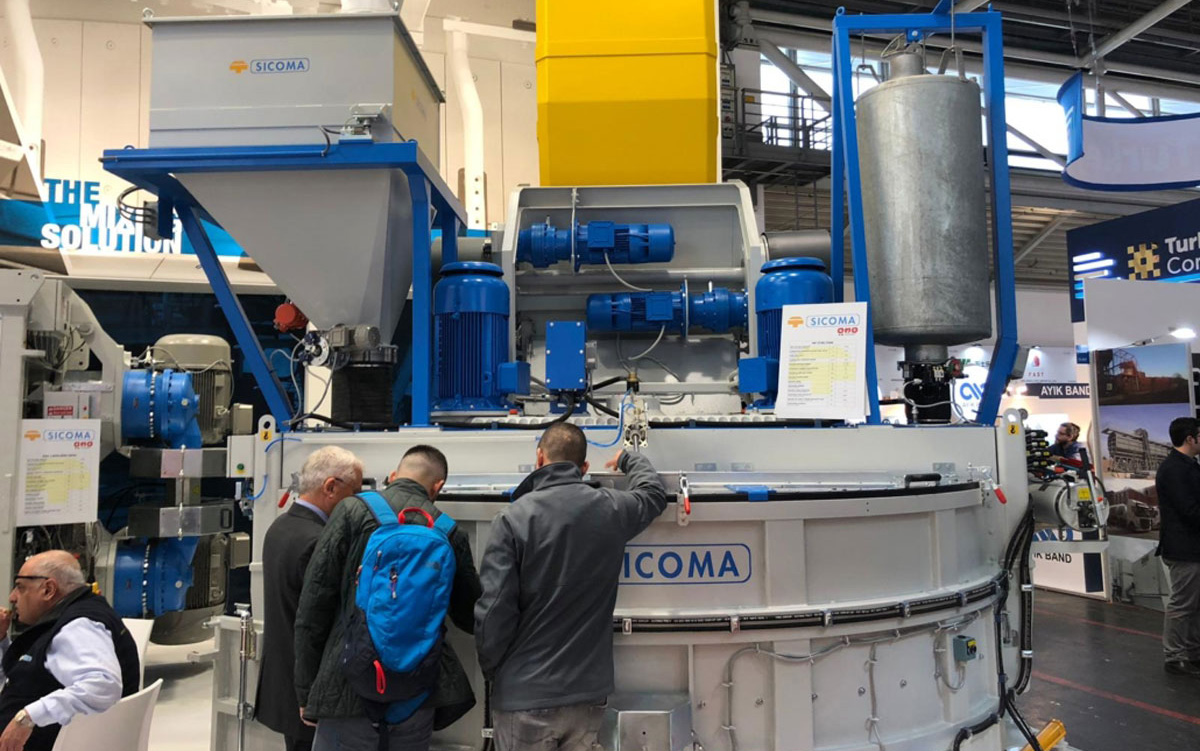

In May 2025, the global construction machinery industry’s spotlight will once again focus on Changsha, China. As the 4th Changsha International Construction Equipment Exhibition (2025CICEE) enters its countdown, this “Capital of Construction Machinery” stands fully prepared. With 300,000 square meters of exhibition space, 1,650 Chinese and international exhibitors, and over 300,000 professional visitors, it […]

2025 Changsha International Construction Machinery Expo: China’s Strength in the Global Industrial Chain Transformation

From May 15 to 18, 2025, the International Convention and Exhibition Center in Changsha, Hunan, will host the annual event of the global construction machinery industry—the 2025 Changsha International Construction Machinery Expo (CICEE). With a theme of “High-end, Intelligent, and Green,” this expo serves as a hub for global technological innovation and industry collaboration […]

Bay of Lights: A Bold Step Forward in Cambodia’s Coastal Transformation

Sihanoukville, Cambodia – April 21, 2025 – Breaking ground in 2022, the $16 billion Bay of Lights coastal development is rapidly taking shape along the scenic shores of Ream Bay in Sihanoukville. Spanning over 934 hectares, this ambitious project combines innovation, progress, and community impact, positioning Sihanoukville as the Next Southeast Asia’s next major economic and […]

2025 Changsha International Construction Equipment Exhibition promotion

After three sessions of careful cultivation, Changsha International Construction Equipment Exhibition(CICEE)has become an industry event integrating international forums, international competitions, cutting-edge technology exchanges in the industry, and global enterprise-style display. The 2025CICEE will be held from May 15 to 18, 2025, at the Changsha International Convention and Exhibition Center and the Changsha International Conference […]

ខ្មែរ

ខ្មែរ